History

2017

fifth generation

As of 2 October 2017 Henkjan Garretsen is appointed as the new commercial director and share – holder at Garvo bv ´feed to my heart´s delight´ in Drempt. In Henkjan, the family business has found a successor who deeply cares about Garvo.

Henkjan (25) is the son of Janine and Herman Garretsen and, as a successor in the family company, constitutes the fifth generation. After graduating from his Engineering Business Studies at HAN, Henkjan first gained work experience in a number of other companies. He has now chosen to fully dedicate himself to taking over and growing the family business.

It´s Henkjan’s task to manage the sales team and to determine the marketing and communication strategies for the company and the Garvo brand, both in the Dutch and foreign markets.

2017

Today and future

Garvo exists 131 years. Where up until 2005, Garvo was a dynamic family business, in which the whole family worked, it’s now become an inspiring company. Looking at its history, the generations of Garretsen from Drempt appear to have, without exception, several similarities.

All the Garretsens are perseverers and innovaters, always interested in progress. The four generations have consciously contributed to the community and to helping others. One thing in particular: they all married very practical women, who were in education and/or were good in bookkeeping and organizing, and who supported the business for the full one hundred percent. Thanks to this corporate culture, employees have always been strongly engaged in the business. Now it has become a company, with the same attitude toward progress. Present CEO, Herman Garretsen, says: “We don’t only produce animal feed. Everything we do here has to be towards making a better world for humans and animals.”

1886

The windmill

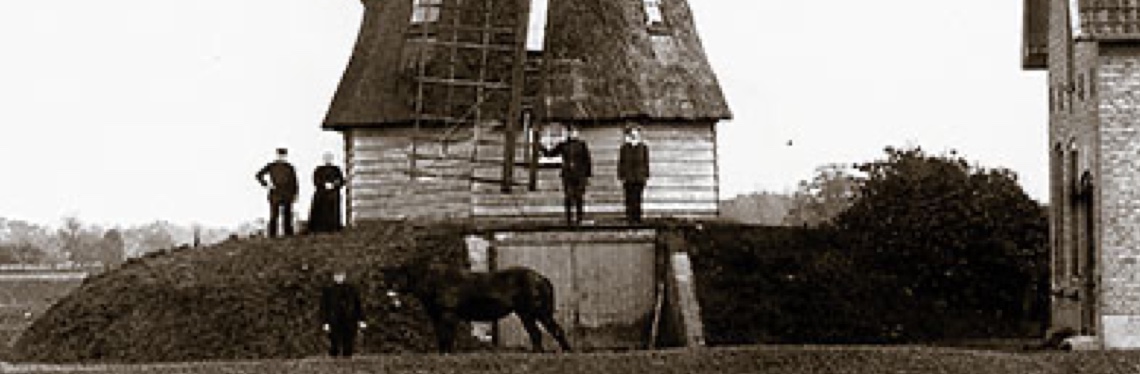

According to the records, the grain mill already stood on its location since the end of the 18th century. In the land registry of 1811, the mill is listed with GM: grain mill, which was thatch-covered with a wooden back wall. When Garretsen takes over the mill, there are many names of the mill attendants who had worked there carved into the wooden beams.

Hannes (known as JB), the great grandfather of the present CEO, Herman Garretsen, was a teacher in Arnhem. In 1886 he heard that the estate called ‘De Ulenpas’ was looking for a new tenant for the windmill with bakery and farm in Drempt. He was interested.

1887

When JB marries Antonia Jolink from Hummelo in March 1887, they receive a bible from the Van Schuylenburgh family, owner of ‘De Ulenpas’ and the mill. On the flyleaf Van Schuylenburgh quoted from psalm 119: ‘Thy word is a lamp unto my feet, and a light unto my path.’

This is a confirmation for the business’ lease.

1895

In 1895, ‘De Ulenpas’ built the mill with a hot bulb engine, so that from then on one could mechanically mill grain. Very modern! The engine used petroleum…until 1909. That was because then, the hot bulb engine became fatal for the business and burnt the whole site down. The business was rebuilt, using this time a 1-cylinder diesel engine from Werkspoor with about 25 hp. The engine powered double mill stones using two yokes. As it was, literally every cent earned by milling the grain of the neighboring farmers was gladly accepted, and Garretsen remained to be known as a miller and a baker.

1917

HWAJ and Antje

1917 was an important year for the business. Hannes’ son, H.W.A.J. (born in 1892 and the grandfather of Herman Garretsen) bought the business, including the house, for 1700 Guilders and rebuilt the bakery from scratch. It now included a circular track for a horse for the mix boiler of the rye bread machine, because making rye bread was too heavy work for manpower. Whereas the first generation leased, the second generation became the owner. H.W.A.J. was also interested in machines and technology and liked to look ahead to the future. The windmill was torn down, having been superfluous for a while already. It can only be seen on old drawings or an occasional photograph.

The Depression

Just like everyone in the 30’s, the business had a long period of lean years. The Depression forced you to be continually on your toes in order to see where you could earn something. Garretsen milled his own grains for the bread as well as grains from the farmers. ‘Adjust, correct and think ahead’ was the motto. In 1936, H.W.A.J. bought a mixer with an elevator, in order to denature the grain during the crisis years. “Heavy work,” said Jan Garretsen.

“We produced only bagged goods, which could be loosely piled . We used coconut- and linseed biscuits in 100 kg slabs in jute bags. My father and the assistants just lifted these onto their necks, something which was completely normal at that time.”

During the war years, the bakery was the most important source of income, namely thanks to the rye bread. Antje, the wife of H.W.A.J., was fantastic in fast mental calculation. That talent had always come in handy, but during the war even more so. For the Dutch who bicycled all the way to the countryside for some food, Garretsen made sure there was always something available. And if ever check-ups took place, then Antje exclaimed quickly to all present the official inventory. The business was never caught for any irregularities! Jan’s wife, Christien (they married in 1953) remembers, even after the war, what happened at the check-ups, “Then grandma Antje said: ‘I see the inspectors coming. Put my bicycle out back quickly and say that I’m not here.’ Antje then walked through the house to the bicycle and just pretended to be arriving. In that way she had enough time to think things through.” Jan: “Every evening we did the books. We sat here together. First from the notebook into the journal, then into the ledger. That’s how it was done then.”

1947

Gerrit Remmelink

The end of the farm

The family stopped running the farm in 1947. H.W.A.J. was acting mayor after the war, and the business offered enough work. Christien: “You shouldn’t have any grand ideas about a farm at that time. There was a total of 3 cows, 20 pigs and 50 chickens. And, of course, the horse was for the circular track and transportation for the mill. We used the milk for the bakery and the rye flour for the bakery and the pigs. A lot of people in this area had small farms like ours. It was safe, and if, for example, there was an outbreak of chicken plague, then you always had the pigs!”

The bakery remained: on Tuesdays and Fridays rye bread was baked, on Wednesdays and Saturdays white bread. That was simply something Jan had a lot of experience in. “The farmers paid a few cents for the milling of their grains, but it was worth it. Look, in the end, we continued with the milling! And that’s still developing. Now it’s an enormous company.”

At that time H.W.A.J. also took over Gerrit Remmelink‘s coal business, which grew substantially in the 50’s. Jan: “It was black gold! In the first place there was a mound of coal in the meadow which we just sold from there.” That quickly changed. After building the first grain silo in 1958, a coal shed immediately followed. Herman Garretsen remembers how he used to help as a child putting coal in sacks: “Together with the man-servant, Bernard. He was quite deaf, and I had a shrill voice, so I could help him.”

1948

The first lorry

Follow-up

In 1948, H.W.A.J. had a heart attack. His son, Jan, was released from military service in order to take over managing the business. H.W.A.J. was never active again in the business. Jan: “And in this way the Firm of H.W.A.J. Garretsen & Son became reality. After that there were continually lots of changes. In 1950, we built the red warehouse, the building where the cleaning installation is today. Following that, the first lorry was bought in 1951 from an army dump: a Commer, which ran on petrol and had a loading capacity of 4000 kg.”

1958

The first bulk product

In the 50’s the business activities expanded with the egg receiving and with the artificial manure business. Not much later, the silos were also filled with lime. The first stone silo was built in 1958 and had 14 cells, and there was a small dumping pit outside. A lot of the materials came from Doesburg, because they could be shipped over the IJssel River. Still, Jan thinks the location in Drempt is ideal: “Being directly on a big shipping river doesn’t only have advantages.”

Silos, artificial manure, coal, building every 4 to 5 years… it was a logical decision to stop with the bakery in 1960. Jan’s interest in the technological developments and in new machines was stronger. He extended the possibilities of the business in 1963 by buying the grain-drying installation which ran on oil. Jan: “We had already experimented with drying, using the process of gas in a wooden mixer through which air circulated. It wasn’t professional enough; combines were the up-and-coming thing! It was the time of quickly increasing bulk development. We built an additional dumping pit, dry chutes and 12 silos with aeration.”

1968

The first pressed pellets

In 1968, the silo was increased in size by 14 cells. In 1970, the first pellet-press installation with hammermill was bought. Herman: “Garvo began with the production of pressed dog food and chicken pellets. I had just finished elementary school and I spent all my free time learning everything there was to learn about the process.” Around the 70’s Garvo also started with the production of pigeon feeds. Herman: “We’d already made mixed grains since 1938, and our machines could meet the requirements of the new demands. It was, therefore, a logical step.”

In 1974, the present cleaning installation was built. Around that time the Netherlands were struggling with a surplus of milk powder, and Garvo began with denaturalizing milk powder. Jan: “And so we switched over from black gold to white gold. We processed tons of milk powder.” Thanks to the milk powder, many related businesses showed interest in mixed grain and pigeon feed. Herman bought an oat-grinding unit. “It could only handle 200 kg per hour, but that it did, and well!”

1980

Fourth generation

In 1980, Herman Garretsen came into the business as the fourth generation. Garvo produced at that time 3000 metric tons of feeds compared to almost 20000 tons now. The weighbridge, the bulk silo on top of it and a resource silo with a large dumping pit were built. Modern: the weighbridge could weigh up to 60 tons and was one of the first electronic platform scales at that time; the time for loading and unloading a freight of feed was brought back to about 5 minutes.

In 1987, Garvo took over Lentink pigeon feed, based in Brummen. In that year there was also a new milling- and mixing line built.

When the business had become a century old, it had grown to include a milling- and pressing installation, a cleaning installation, a (muesli) grain mixer and an office at home. The trend: animal feeds. And not only more feeds for professional farmers, but also feeds for pet and hobby animals, beginning with dogs, chickens and pigeons. This direction was set down and followed. In 1992, the blue storage shed was built, with a surface area of 1000 m². Feeds for animal hobbyists and fanciers grew into the specialty, and in 1995 Garvo stopped producing bulk feed for the farming sector. From that moment on all attention was focused on the more than 100 sorts of hobby feeds and the continual improvement of their quality.

The technical possibilities also kept increasing. In 1998, there was another expansion concerning the production of mueslis: a silo with 28 cells and a completely automated weighing scale and mixing line. Garvo also invested in an automated bagging machine and a palletizer for piling the bags. In 2008, the first attempt was made to further automate dosages within the production process and to improve the control of the milling and mixing line. This all was wrapped up in2010, with further investments in computers and software for bookkeeping and recipes. The most recent new building is the office, which was opened for use in 2011.